Buying Guide for Cut-Off Wheels

A cut-off wheel is a thin disc of abrasive material that is used for cutting metal, plastic, or other materials. They are also known as abrasive wheels or grinding discs. Cut-off wheels are available in various sizes, materials, and grits to suit a variety of cutting applications. Cut-off wheels are used on various power tools, including angle grinders and chop saws. They are also used in air tools such as pneumatic die grinders and air cutoff tools.

Cut-off wheels can cut metal, plastic, stone, tile, glass, and more. When choosing a cut-off wheel for your application, select the right size, material, and grit. The wrong choice can damage your workpiece or tool.

Explore our wide range of cut-off wheels to find the best options for you.

Benefits of Cut-Off Wheels

Cutting through Hard Materials

Cut-Off Wheels are thin, disc-shaped abrasive wheels that are used for cutting through hard materials like metal, stone, and concrete. They are typically made from durable materials like carbon steel or aluminum oxide. Cut-Off Wheels can be used with a variety of power tools, and are typically used to make quick, clean cuts in hard materials.

Easy to Use

Cut-Off Wheels make it easy to use by providing a clean, straight cut every time. They are perfect for cutting through metals, plastics, and other materials with ease. Plus, they are designed to last long, so you can use them over and over again.

Versatile

Cut-Off Wheels are great for versatile because they can cut through a variety of materials quickly and easily. This makes them perfect for versatile applications where you need to be able to cut through different materials quickly.

Low Cost

Cut-Off Wheels are used to help Low Cost because they are very powerful and can help to get the job done quickly. They are also very versatile and can be used on many different materials.

Factors to Consider Before Buying Cut-Off Wheels

Cutoff Time

The cutoff time is the time at which the abrasive wheel is disengaged from the power source. This is generally expressed in minutes. Abrasive wheels are made of different materials, including aluminum oxide, silicon carbide, and diamond. Each type of abrasive wheel has a different cutoff time. For example, aluminum oxide wheels have a cutoff time of 1 minute, while silicon carbide wheels have a cutoff time of 5 minutes.

Material Thickness

Material thickness matters while buying a Cut-Off Wheels because it determines how much material can be removed and how long the wheel will last.

Arbor Size

Arbor size is one of the important factors to consider while buying a Cut-Off Wheels. It is the inner hole diameter of the wheel. A too small arbor size may cause the wheel to become unbalanced, and a too large arbor size may cause the wheel to wobble.

Wheel Size

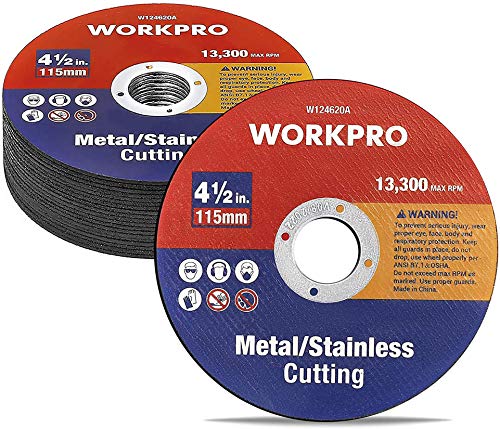

Wheel size is a important aspect to consider while buying a cut-off wheel because it affects the diameter of the wheel and the thickness of the cut-off wheel. If the wrong size is chosen, it can cause the cut-off wheel to break.

Conclusion

Cut-off wheels are classified as abrasive wheels and discs. They are used for cutting and grinding. There are different types of Cut-Off Wheels available in the market. Some are made of steel, while others are made of aluminum oxide. Cut-Off Wheels are available in several sizes and thicknesses. The thickness of the wheel determines the depth of the cut.

The size of the wheel determines the width of the cut. Cut-off wheels are used in different applications such as cutting metal, stone, and grinding metal. To know your buying choices, head over to our featured section. We review and recommend leading products based on their sizes, prices, and material thickness. After reading hundreds of reviews, we recommend top cut-off wheels.