Buying Guide for 3D Printers

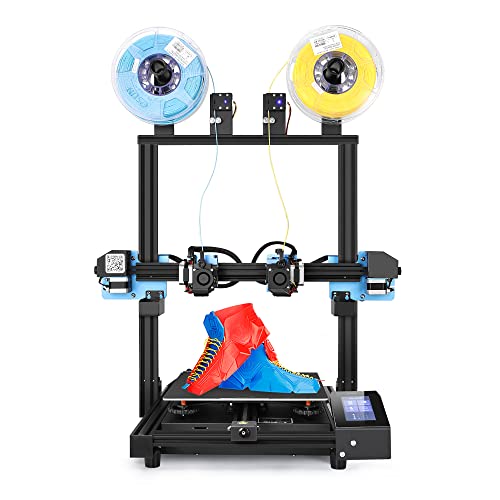

Do you need a method for producing product prototypes and models quickly? Not a problem! 3D printers are here for you. A digital file can be used to create three-dimensional solid things via additive manufacturing, also called 3D printing. In an additive process, layers of material are added one at a time until the outcome is achieved. Each of these layers can be viewed as a thinly sliced cross-section of the item. Among the items made with 3D printers are shoe designs, furniture, wax castings for making jewelry, tools, tripods, gift and novelty items, and toys. Explore our wide range of3d printers to find the best options for you.

Benefits of 3D Printers

Rapid Prototyping

The 3D printer's ability to produce items in a matter of hours speeds up the prototyping process. Each stage can now be completed sooner thanks to something like this. A 3D printer is less expensive than machining prototypes and speeds up the process of finishing each complete redesign.

Print on Demand

In contrast to standard manufacturing techniques, print on demand has the benefit of requiring less space for inventory storage. This conserves both space and money because it is not always necessary to print in large quantities. The 3D design files are all saved in a virtual library where they can be found and printed as needed because they are printed using a 3D model as either a CAD or STL file.

Ease of Access

As more local service providers offer manufacturing outsourcing services, 3D printers are getting more and more affordable. Compared to more conventional manufacturing procedures manufactured elsewhere, this saves time and does not necessitate high transit expenses.

Freedom of Design and Complexity

One of the key advantages of 3D printing is the freedom of design. You can replicate all of your ideas and make them into real objects. Printing is a viable option for even the most complex forms. You can overcome the constraints imposed by traditional manufacturing by using 3D printing,

Factors to Consider Before Buying 3D Printers

Material

The kind of material and 3D printer you use depends depend on what you plan to manufacture. Different types of material can be supported by various 3D printer types. The characteristics of different 3D filaments vary greatly. If you want beautiful, aesthetically pleasing filaments, then SILK or PLA will be the right choice for you. If you need a strong and light filament, you will print the PAHT filament with carbon fiber. It is important to know the properties of the materials with which you will 3D print.

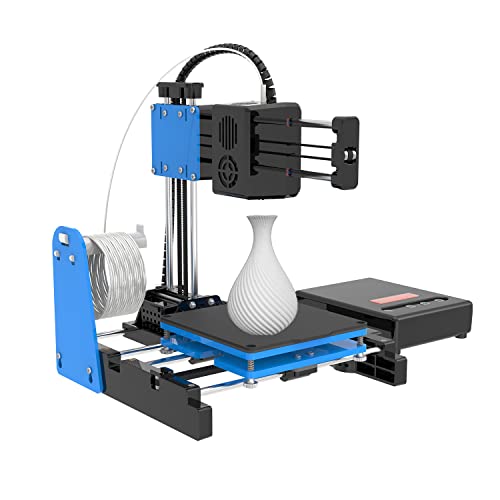

Build Volume

The build volume refers to the printing area. The most exact size to print on should be considered while selecting the printer. The simple solution of buying a big printer that can accommodate all print sizes is not practical. As printer costs increase, the quality of smaller, more delicate prints may suffer. A 350mm–500mm printer would be ideal if you wanted to scale up the size of your 3D creations, as the typical printing size of a 3D printer meant for general use is approximately 150–300mm. Explore our selection of 3d printers with excellent build capacity and build volume.

Features

When you decide what type of printer you would like to get, you should check out the features you want your printer to have. Some FDM printers can cool the nozzle when you are done printing, and some other printers can move the nozzle away after printing to prevent overheating or the production of excess filament. Apart from these safety features, be sure to check for other features like; type of plate, touchscreen interface, build volume, print bed size, sensor filament, bed leveling, does it have a direct drive extruder or a Bowden tube system, Wi-fi connection, diameter of filament.

Resolution

The finishing of the printed object and the printing of fine details are directly impacted by resolution. The smallest of features may be printed with ease on a printer with high resolution, and the layer height will be smaller, resulting in a smooth surface finish. Long-term advantages of investing in a 3D printer with a high resolution can be substantial. The best resolution for printers is about 20 microns for SLA/DLP, 60 microns for SLS, and 100 microns for FDM.

Conclusion

3D printing technology has revolutionized the way we design and manufacture products. It has brought about numerous benefits, including faster prototyping, reduced waste, and increased customization options. Technology has enabled small-scale production and has made it possible for individuals to produce their customized products. After reading hundreds of reviews, we recommend top 3d printers.